At A.R.E. Manufacturing, Inc., we’re constantly focused on delivering the highest precision, the fastest turnarounds, and the most consistent results for our customers. One of the key ways we achieve this is through our Dedicated Tooling System. This system allows us to efficiently and accurately produce parts while minimizing lead times and ensuring quality every time.

What is a Dedicated Tooling System?

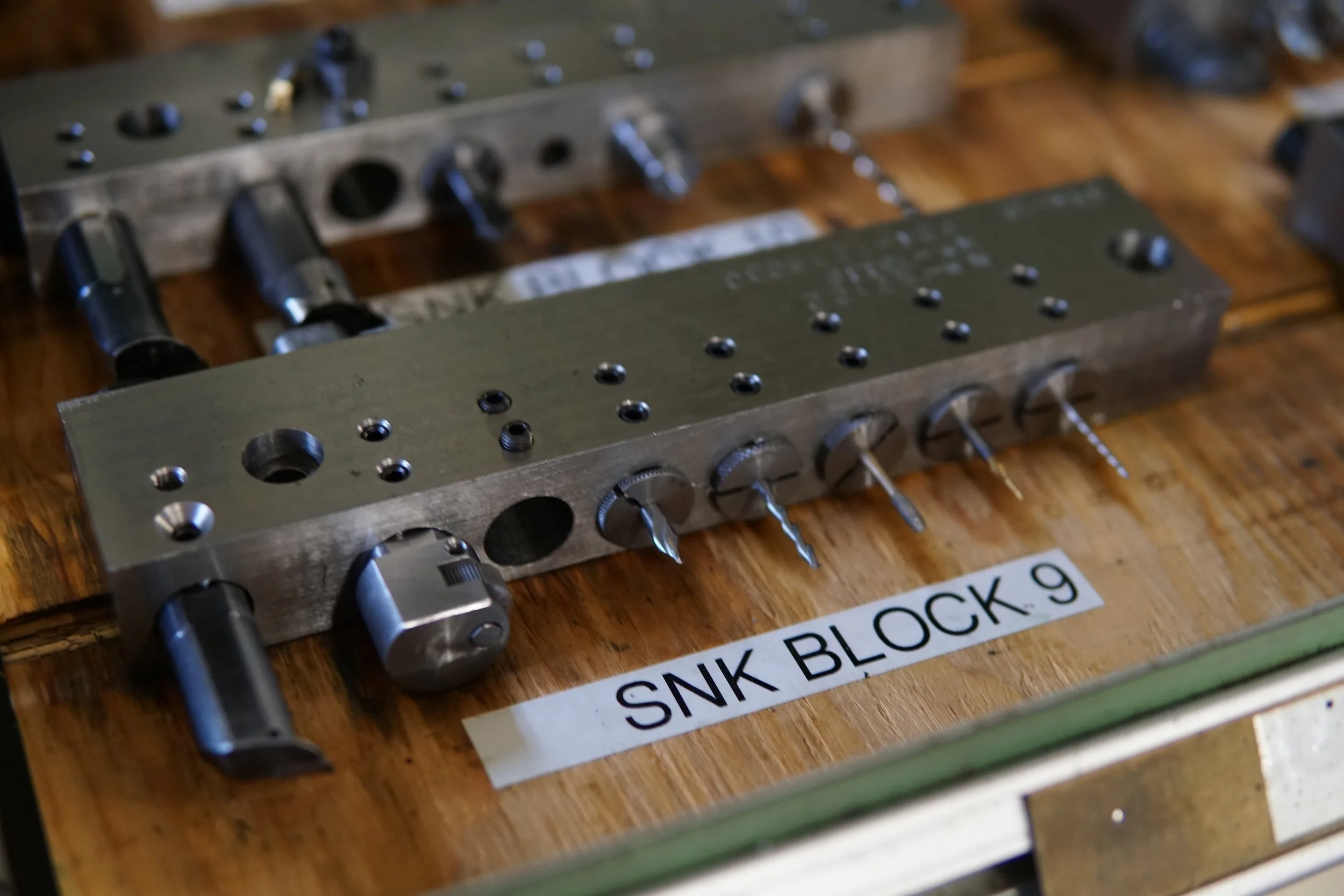

Every time we program a new part, we identify and assemble the most efficient and effective tools required for the job. From cutting inserts and end mills to collets, toolholders, and everything in between, we carefully put together each toolset needed to execute the required processes. This attention to detail ensures that we’re using the right tools for every operation, reducing setup times and optimizing production from the very first cut.

Once we’ve completed a run of parts, the real power of our dedicated tooling system comes into play. We keep the tooling assembled after each job. Instead of breaking down and rebuilding the tooling for your parts each time you place an order, we carefully document every component of our setup and catalog the assembled tooling for storage. The result is a fully optimized toolset, ready for the next order.

To keep everything organized, we store these dedicated toolsets in our over 500 sq. ft. vertical storage system, ensuring that each set is easily accessible and can be retrieved quickly.

Fast, Consistent Setup for Every Order

Here’s where it gets even more efficient: when you place a repeat order for a part, we don’t need to waste time searching for the right tools or trying to remember which specific setup was used previously. Instead, we simply retrieve the pre-assembled toolset from our storage system, set it up on the machine, and start producing parts immediately. No reprogramming, no tool hunting, and no setup delays.

This streamlined process has several key advantages:

Reduced Lead Times: With pre-assembled tools ready to go, we can get to work faster and deliver your parts more quickly.

Consistency Across Runs: By using the same tools and setups for each order, we ensure that every part meets the same high-quality standards, with no variation between runs.

Improved Efficiency: There’s no need to reinvent the wheel each time we run your job. We eliminate the inefficiencies of reprogramming, reassembling, and searching for tools, so your parts are produced faster and with greater precision.

Your Benefit: Faster Delivery and Unmatched Consistency

Our Dedicated Tooling System is designed to give you the best of both worlds: faster lead times and reliable, repeatable results. ARE excels at repeat, recurring orders by delivering precision parts faster, with less downtime, and without sacrificing quality.

We’ve streamlined our process, ensuring that you can rely on us to get the job done—on time and to your exact specifications—every time.

Experience the difference in efficiency and consistency. Contact us today to learn how our dedicated tooling system can help speed up your next project.