In aerospace manufacturing, timelines are tight, tolerances are unforgiving, and there is no room for error. At ARE Manufacturing, we’ve built our processes to meet those demands head-on.

Tight Timelines

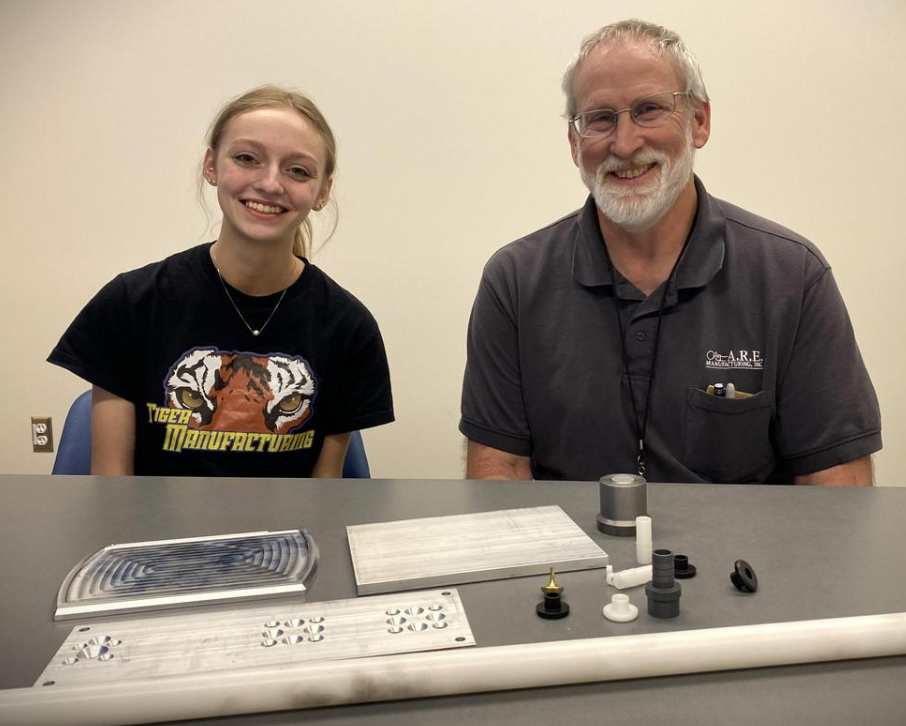

Recently, one of our aerospace customers needed precision parts for a helicopter spray system on an expedited schedule. Because of our one-stop setup process, we were able to respond quickly and meet their due date, without sacrificing quality or documentation needs.

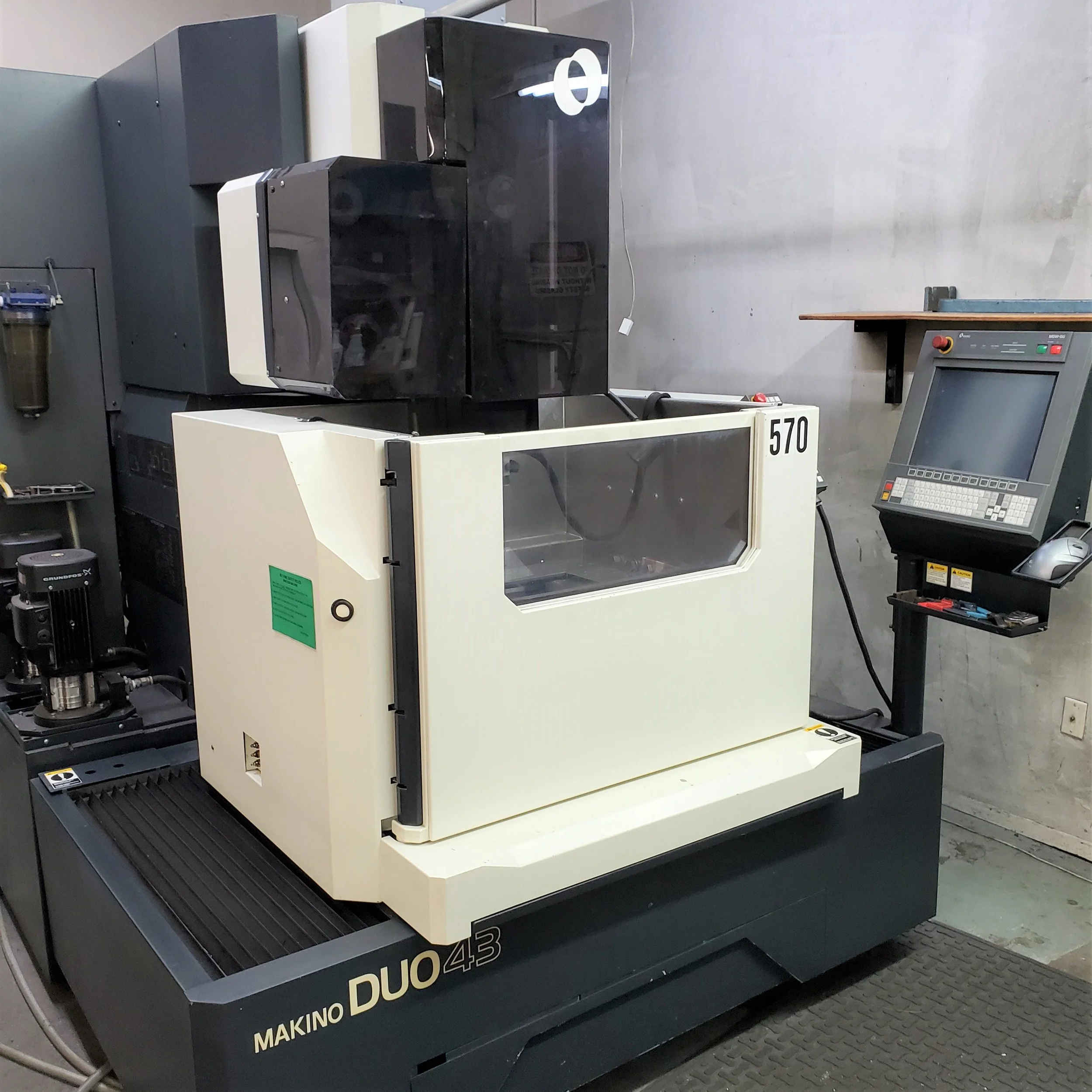

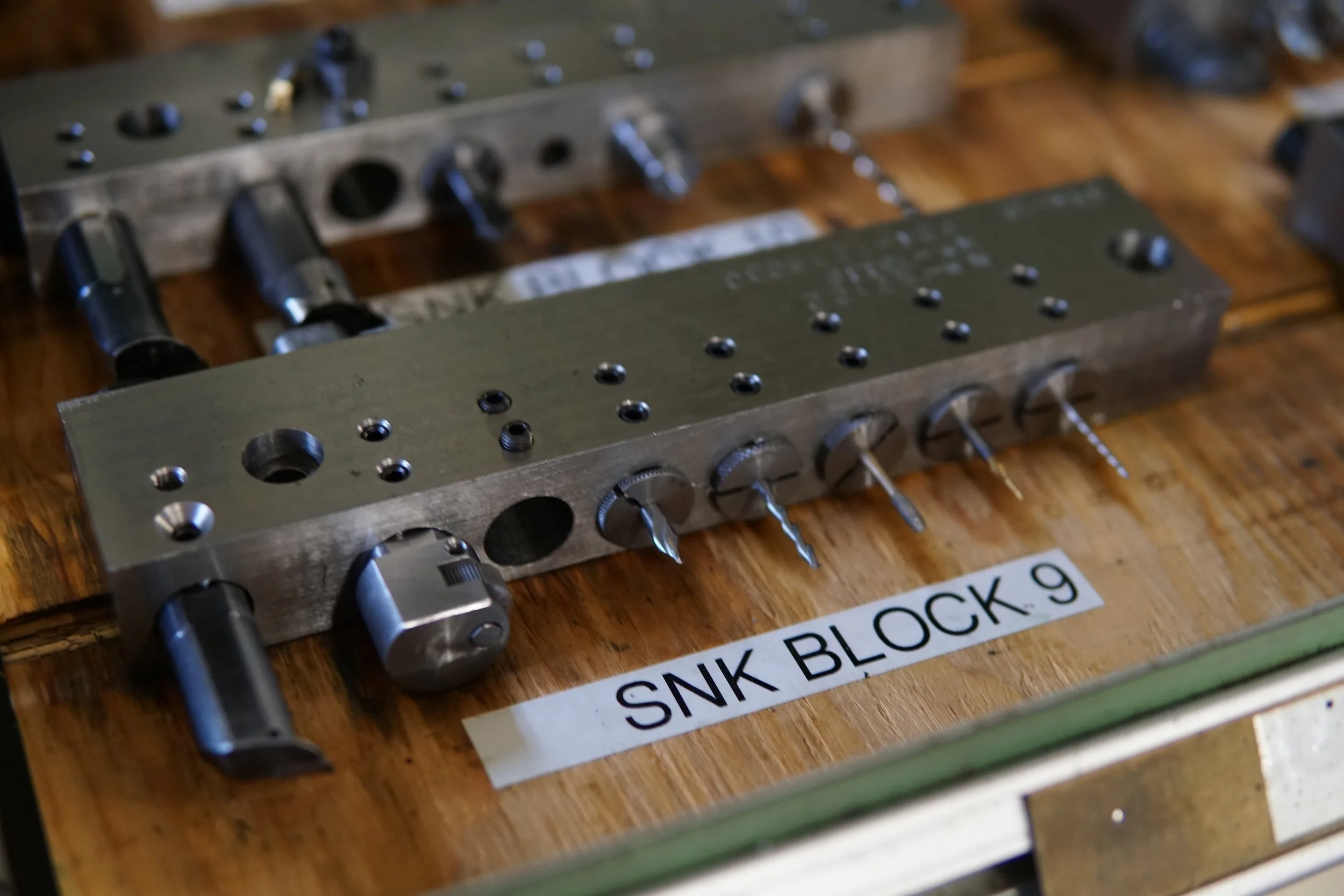

Each job at ARE is dedicated to a single, expert machinist to program, prove out, and run production. This eliminates unnecessary hand-offs between departments, reducing delays and ensuring accountability from start to finish. The result is faster turnaround and consistent results, even on complex components.

Unforgiving Tolerances

That same machinist who programmed the job also inspects the finished parts as they come off the machine. GD&T requirements are then validated and documented using our in-house CMM. Again, our one-stop process keeps hand-offs to a minimum and production moving forward.

Documentation and Certifications

When it’s time to ship, our ProShop ERP system allows us to quickly generate complete, customer-specific documentation packets. Material certifications, inspection reports, and traceability records are delivered exactly as required - no delays, no surprises.

Our integrated approach allows aerospace customers to partner with us in confidence. Regardless of the type or size of order, we strive to uniformly align with our customers’ material, quality, and delivery standards throughout every step of the process.

At ARE Manufacturing, we simplify the complex.