When your part design includes internal hexes, splines, or intricate through-features, the most cost-effective and quickest way to produce your parts is with Wire EDM. At ARE, we have in-house Wire EDM capabilities so that we can meet your tight timelines and keep our prices competitive.

What is Wire EDM?

Wire Electrical Discharge Machining (EDM) uses an extremely thin (.004 dia.!), electrically charged wire to cut conductive materials – without ever touching the workpiece. To “cut” the material, a voltage is applied between the wire and the workpiece, causing sparks to short-circuit the gap between the two and erode the material. The wire is CNC-controlled, so any intricate shape can be produced.

Why use Wire EDM?

Unmatched accuracy on the most complex geometries

No tool wear, deflection or vibration - even on hardened or heat-treated materials

Minimizes distortion in final product

No need for costly special tooling

Perfectly clean edges with little to no deburring needed

The Difference on Your Bottom Line

Pairing ARE’s in-house Wire EDM capabilities with our standard CNC machining services lets your project stay under one roof. Our one-stop-shop experience means:

Predictable lead times - no waiting on outside vendors

Cost savings - no third-party markups

Flexibility - design changes or rush jobs can be handled immediately

Optimized Efficiency – matching part features to the best manufacturing process

One point of contact - our team manages your project from start to finish

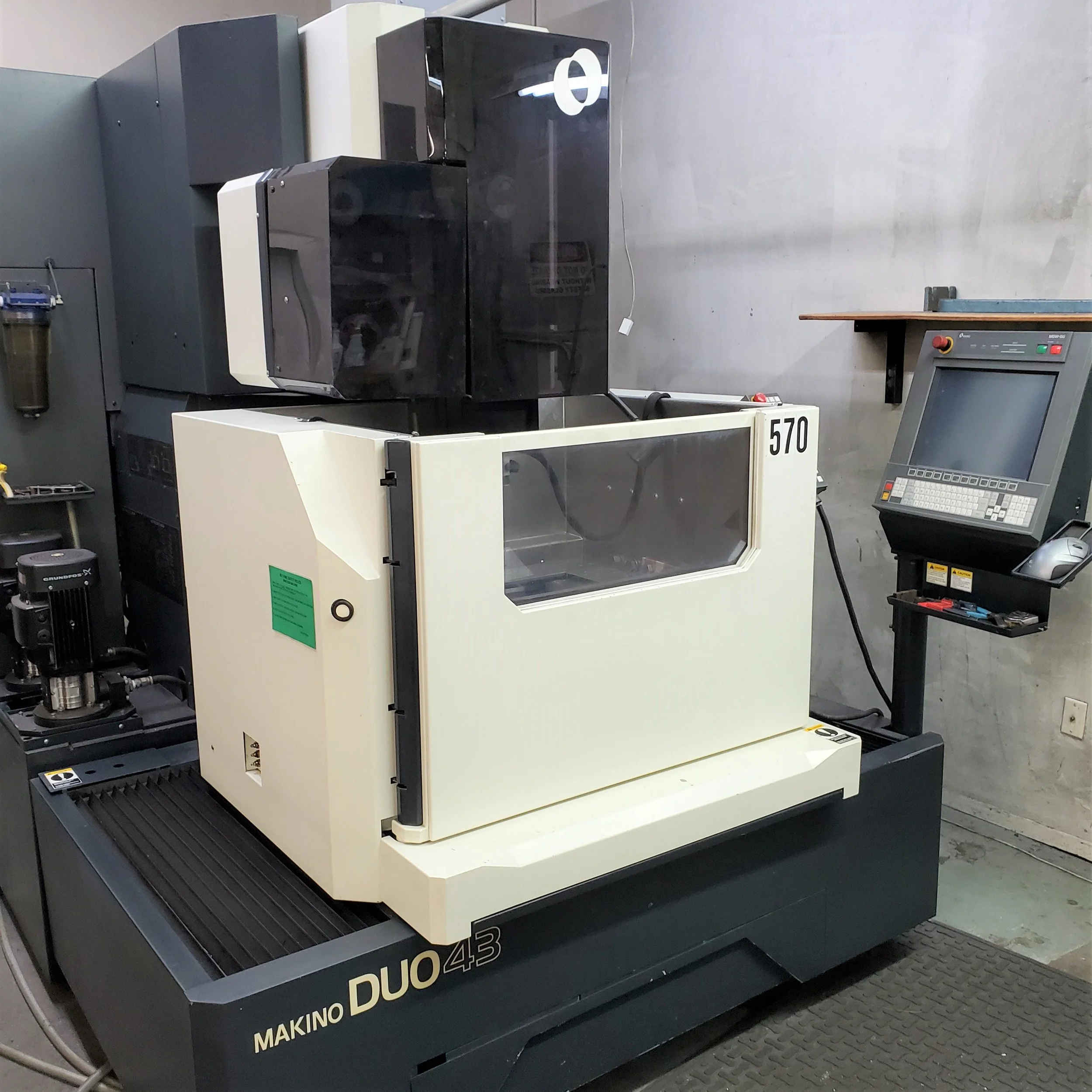

Our Makino Duo 43 Wire EDM offers the precision and flexibility your parts demand:

Work Envelope: 33.5" x 28.3" x 12.6"

Wire Diameters: .004"–.012"

Taper Cutting: up to 15° in 4" material

Auto Wire Threader

Dual Spark Generator

Advanced Flushing System

Contact A.R.E. today to put your project in motion. Our team is ready to show you how we turn challenging geometries into delivered parts. At A.R.E. Manufacturing, we simplify the complex.